Posted by Josh Elijah on 15th Jul 2023

UbiSwitch Airborne Tests

Qualifying UbiSwitch for Aircraft use

There are generally two approaches to testing appliances for use, lab testing and in field testing. At BotBlox, we are pursuing both to give our customers the highest level of confidence in our hardware. To achieve this, we are not only engaging with our test lab partners for MIL-STD-810G testing (results expected in November 2023) but also directly with customers who are already using and deploying UbiSwitch in their systems.

One such customer is an unnamed company currently developed airborne imaging systems for defence application. This customer is using UbiSwitch as part of the core communications backbone to transport around image streams and control data to and from onboard sensors, actuators and a main computer. To have the confidence in their system, they have subjected UbiSwitch to a number of temperature and altitude tests while installed in their communications system.

This post aims to highlight the basics of the testing currently done on UbiSwitch by our customer, and while this is not a replacement for full MIL-STD-810G testing, it does cover some of the core tests necessary for using UbiSwitch on an onboard platform.

Test setup

A simulated data load of 5 cameras was used for this test, and the status of each simulated camera was monitored, along with the resulting image data being monitored for integrity. A correct operations is shown by all simulated cameras being active and the resulting image data being intact.

UbiSwitch was installed into a metal chassis alongside a number of other electronic devices, together making up the core communications backplane.

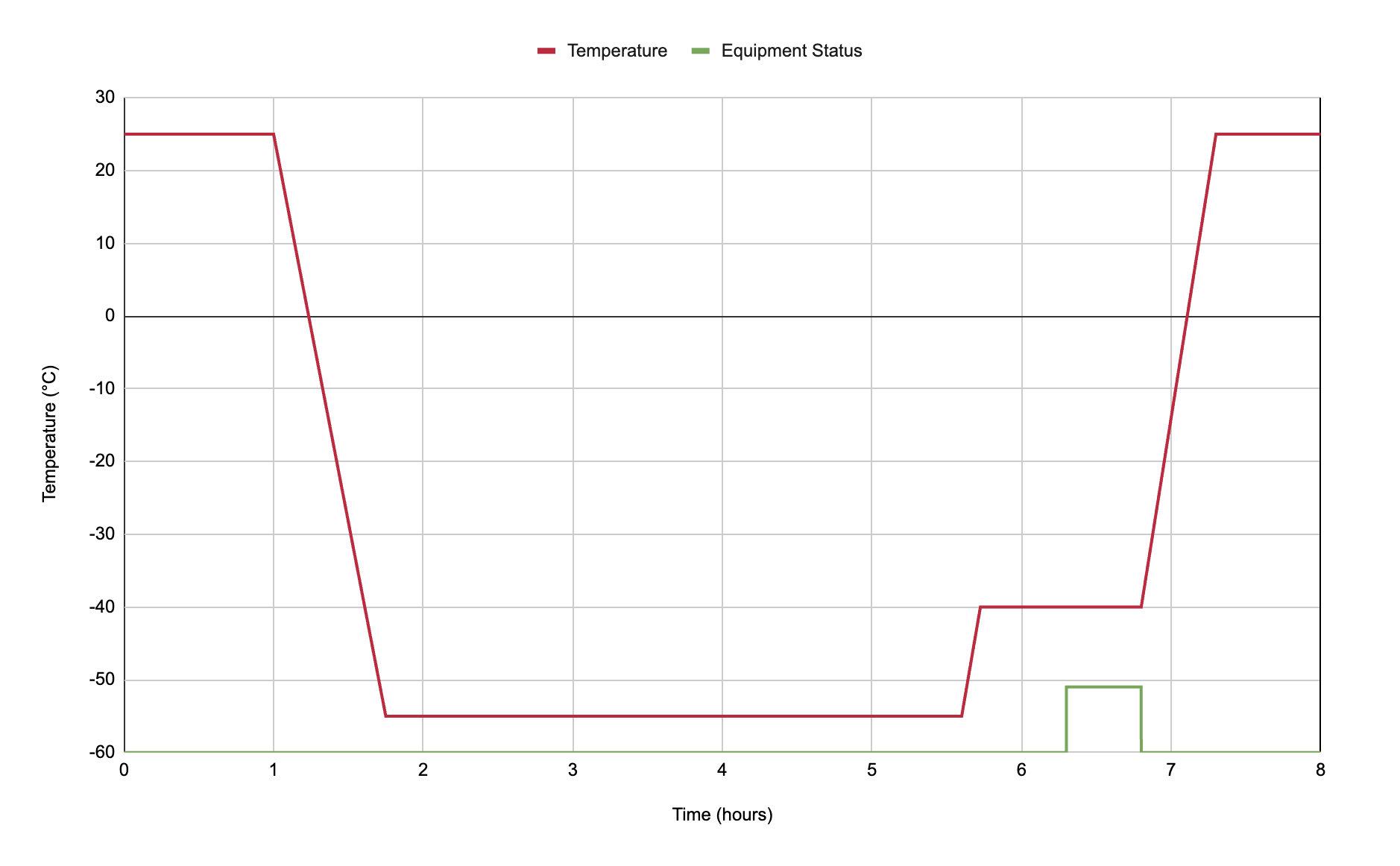

Low Temperature Test and Short-Time Operating Low Temperature Test

UbiSwitch was subject the the temperature profile shown in figure 1 below and was shown to be operational for the entire time that the equipment was turned on.

UbiSwitch was subjected to the profile shown above, which involves a long dwell period at -55°C to stabilise internal temperature, followed by the device being turned on for 30 minutes at -40°C.

UbiSwitch was functional for the entire 30 minute period.

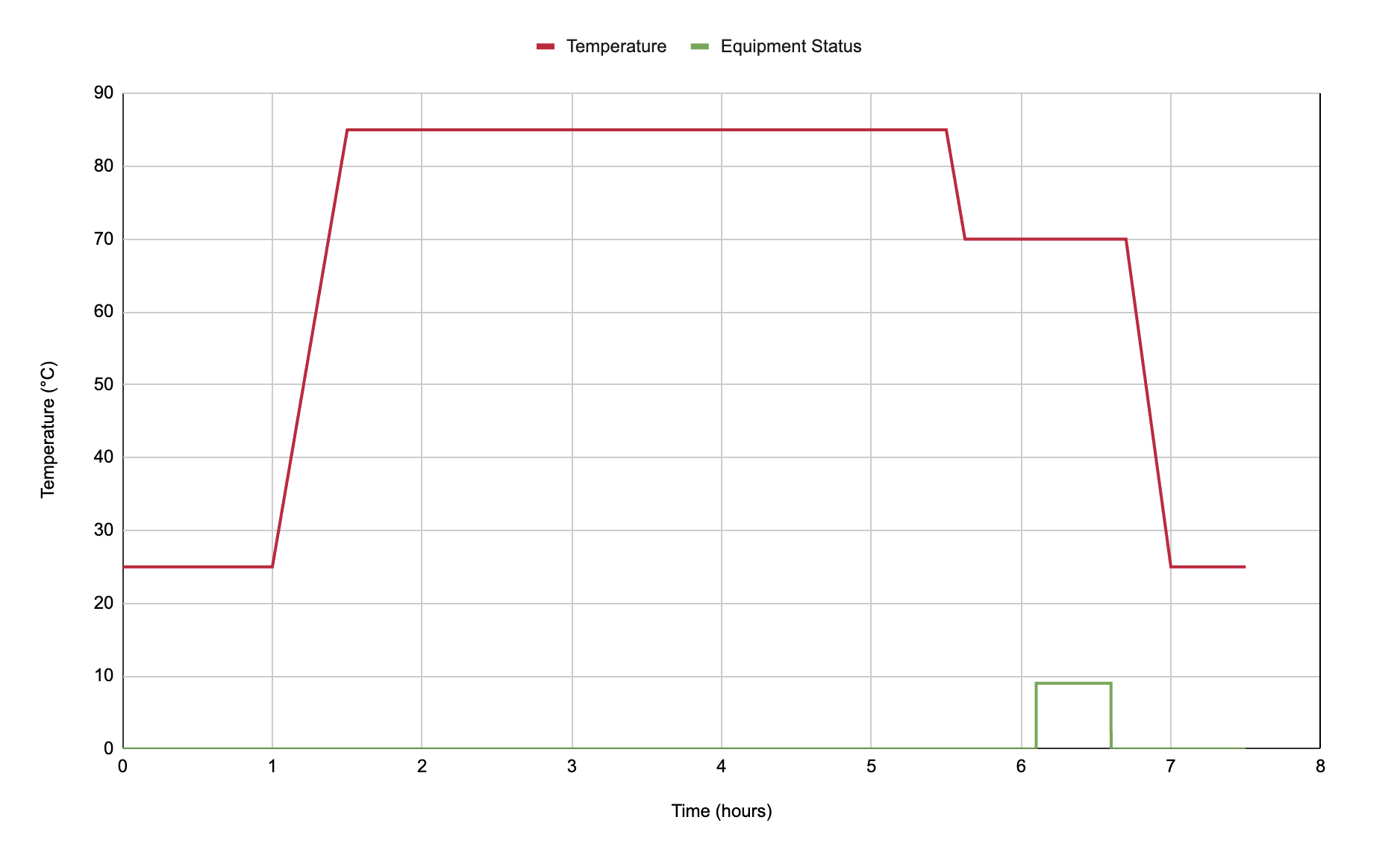

High Temperature Test and Short-Time Operating High Temperature Test

UbiSwitch was subjected to the profile shown above, which involves a long dwell period at +85°C to stabilise internal temperature, followed by the device being turned on for 30 minutes at 70°C.

UbiSwitch was functional for the entire 30 minute period.

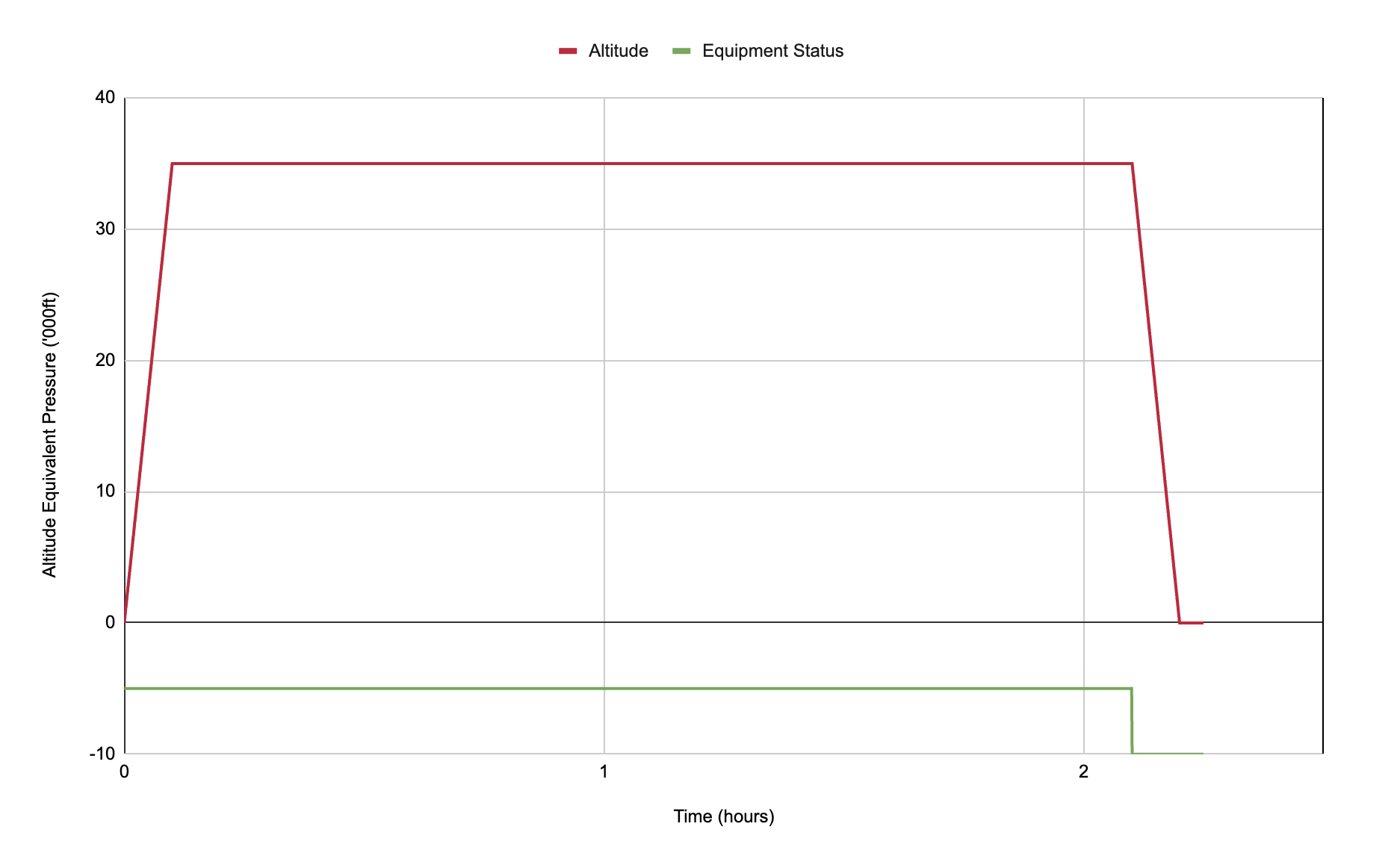

Altitude Test

UbiSwitch was subjected to the altitude test shown above, while involved operating for 2.1 hours while at 30,000ft equivalent pressure, at 25C ambient temperature.

UbiSwitch was functional for the entire 2.1 hour period.

Conclusion

UbiSwitch showed flawless performance at these initial performance tests, and our customer has gone ahead with integrating UbiSwitch into their airborne equipment. We have also gained a lot of confidence that UbiSwitch will pass MIL-STD-810G tests without issue