Posted by Josh Elijah on 18th Sep 2023

Designing NDAA and Executive Order 13981 Compliant Drone Components: A Short Guide

Designing NDAA and Executive Order 13981 Compliant Drone Components: A Short Guide

The National Defense Authorization Act (NDAA) and the Executive Order 13981 are vital regulatory measures aimed at mitigating the global dependency on China for key components in the tech and defense sectors. The crux of these regulations is to foster secure supply chains, rejuvenate non-Chinese manufacturing industries, and decrease potential vulnerabilities. For the drone and Unmanned Aerial Systems (UAS) realm, the relevance of these orders cannot be understated. Executive Order 13981, in particular, has proven to be more incisive in its effects than the NDAA, pushing industries towards a more secure manufacturing landscape.

Update as of 18 November 2023. Recent updates to the NDAA bill (Fiscal Year 2023 NDAA Sec 817) have changed the meaning of NDAA compliance to be far more aligned with EO 13981. Read more about that here.

Understanding EO13981 Compliance:

Navigating compliance with Executive Order 13981 requires discernment. While one may intuitively understand the need to circumvent Chinese-made components, the intricacies often lie in the details. A shocking 95% of the world's rare earth elements, crucial for various components, are sourced from China. Neither NDAA nor EO13981 provides a step-by-step guide to achieve full compliance, emphasizing the need for a well-informed and transparent approach.

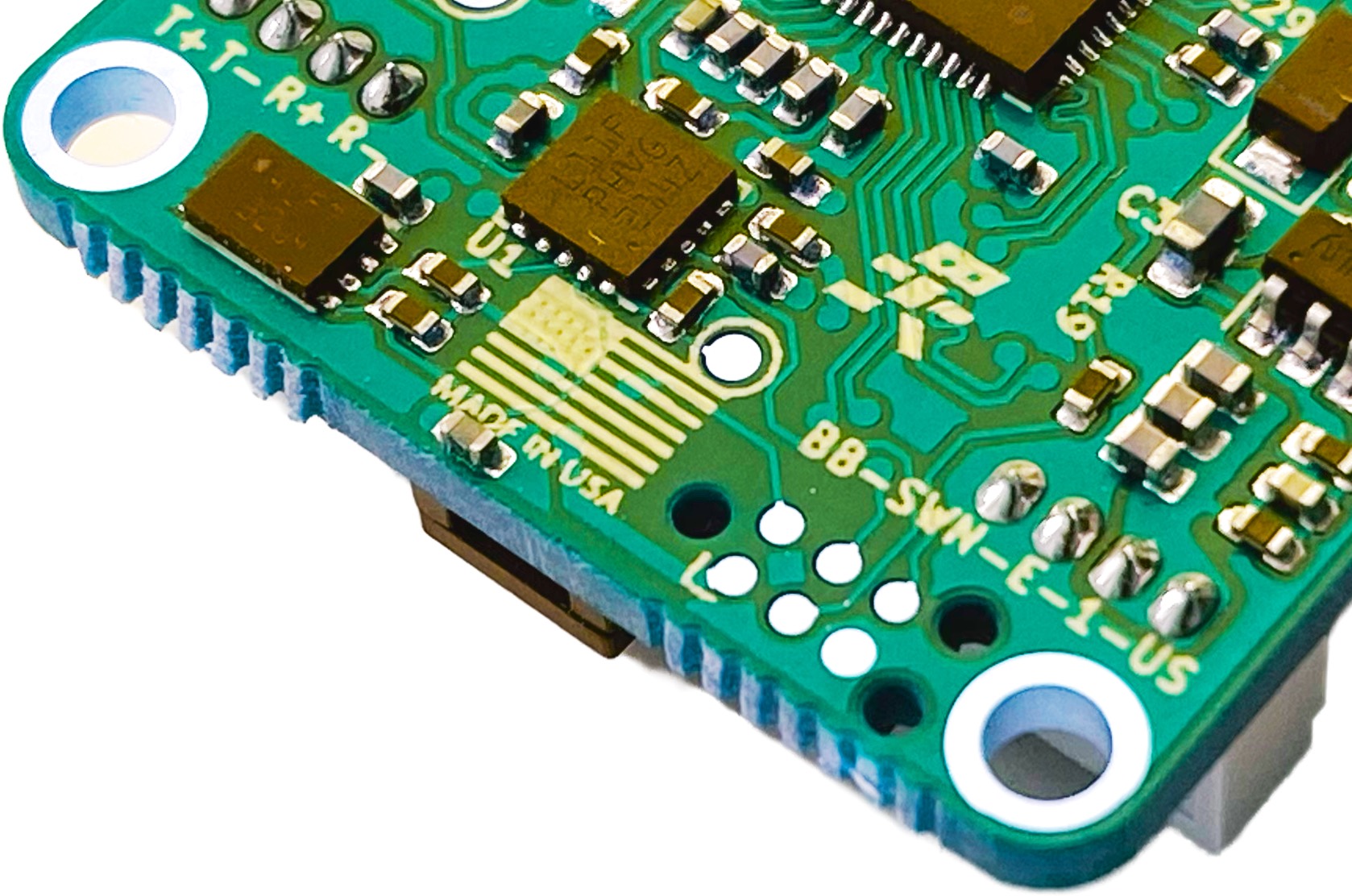

Deconstructing the Printed Circuit Board (PCB):

Let’s take the PCB as an example (conveniently this happens to be the kind of products we at BotBlox manufacture). A PCB is a good example because it’s somewhere between a basic raw material and a complex machine like a fighter jet. A PCB is an intricate meld of epoxy-soaked fiberglass and copper, with various components soldered to it. Where it's made holds significance, especially given the potential risk of design file transfers to antagonistic nations.

To consider NDAA and EO13981 compliance, let’s consider the various components involved:

PCB: China is dominant in PCB manufacture, accounting for around 52% of global PCB manufacture in 2020. Coming second was Taiwan (11.5%), followed by South Korea (10.8%) and Japan (8%). The Americas make up just 4.9%, and Europe, 3.7%. Put simply, pick a country other than China. Aside from China, at Botblox, we manufacture in the USA, Estonia, Thailand and the UK.

Chemicals: Take an educated approach. Sourcing flux or isopropyl alcohol from China is probably inconsequential and, in some cases, difficult to avoid. At BotBlox we tend not to spend too much time worrying about the source of simple chemicals like this. The same is not true of chemicals like solder paste, especially if it is high performance like eutectic solder which is high cost and of critical strategic important (eutectic solder is used in space). In these cases, it is always better to source it yourself and consign it directly to your manufacturer. This allows you to purchase directly from a solder manufacturer. Remember, your PCB manufacturer’s incentives are to minimise cost rather than to help you achieve NDAA or EO13981 compliance.

Passive components: An 0402 resistor from China isn't alarming, but other options are available. Many passive components are now manufactured in Thailand and the Philippines, as increases in Chinese wages has actually pushed a lot of the low margin passive component manufacture out of China. Passive components typically make up 20-30% of overall BOM cost for BotBlox, so it does warrant a good level of attention to avoid Chinese sourced parts. You may think you can make it easy by simply buying the components from a US distributor. But remember, the distributor is not the manufacturer. Instead, take note of the manufacturers of each part, and invest time in learning where their manufacturing bases are.

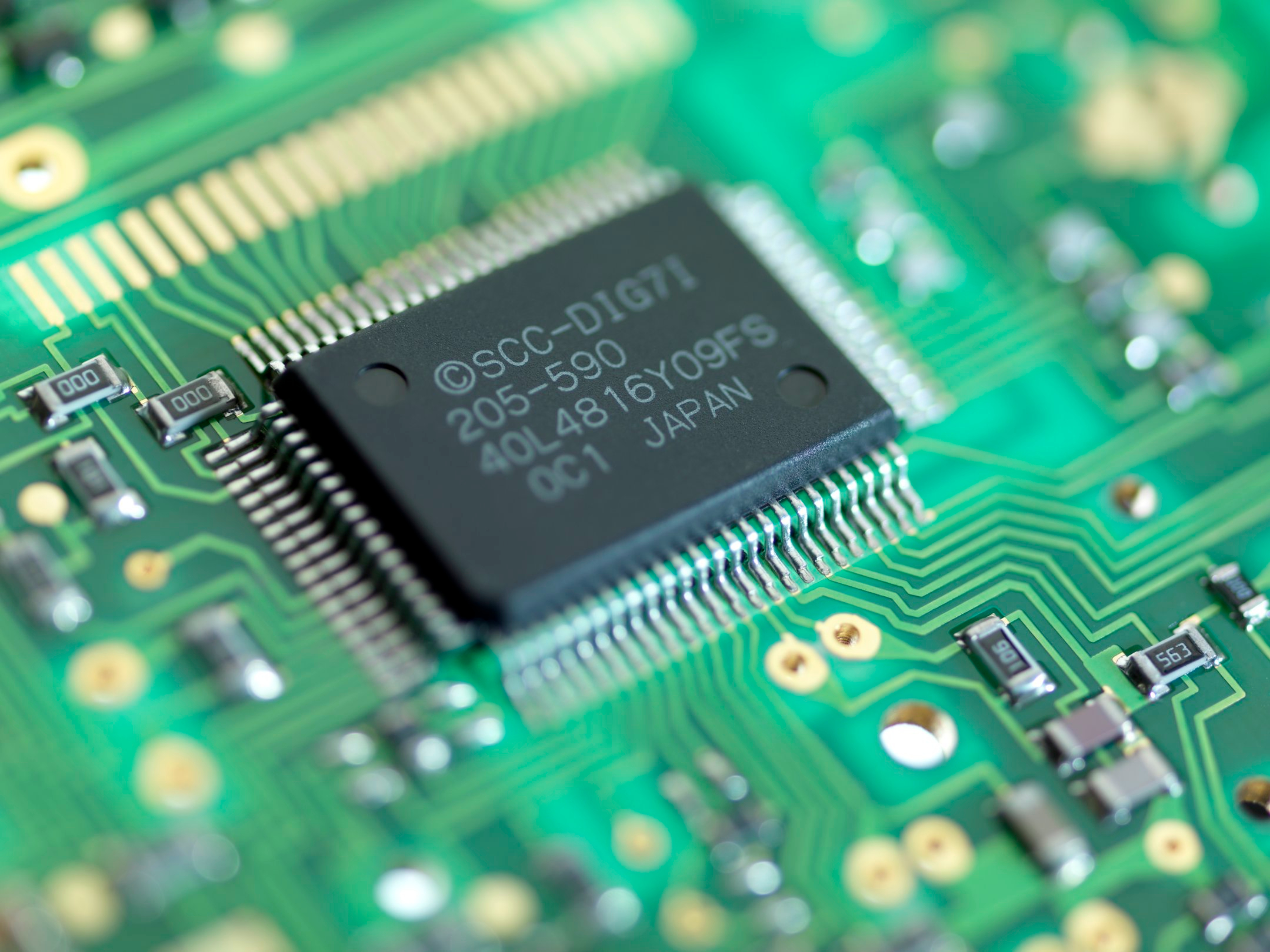

Active components: ICs (Integrated Circuits) demand meticulousness. They typically make up 70-80% of the BOM cost of BotBlox boards, and they carry the core functionality that makes our technology possible. They shouldn't have any association with Chinese soil. Steer clear of suppliers from Shenzhen and Hong Kong due to potential counterfeiting risks. At BotBlox, we buy our chips directly from the manufacturers (MicroChip Ltd, ICPlus), or from trusted distributors that can provide full chain of custody documentation.

Large components: While it is unlikely, these can harbour concealed hardware. Dive into their origins, eschewing mere superficial checks. There is one part we use, an SFP cage with a significantly unique footprint, that is incredibly difficult to purchase from a non-chinese company. In this case, we inspect each part thoroughly prior to consignment to our manufacturer. Longer term, we’re redesigning the board to accommodate a Japanese manufactured SFP cage instead.

Physical Location: Ensure your boards avoid Chinese territories during their entire manufacture process.

Document every step. Transparent, detail-oriented processes aid in instilling trust among discerning customers.

Choosing a Manufacturing Base:

While the US might seem the natural choice, especially for winning the trust of American clients, cost considerations can lead businesses elsewhere. Neither NDAA nor EO13981 dictates a US-only manufacturing preference. Potential alternatives include Mexico, Estonia, Thailand, and Vietnam – all known for robust electronics industries and friendly relations with NATO.

Beware of Shifty Practices:

Unethical businesses might manufacture in China, then re-label components after shipping them to another nation. Vigilance is crucial to avoid this. At BotBlox, we are working with an authentication process that will allow our customers to directly confirm that a specific board was indeed manufactured with them. This is not always ideal, as our manufacturers are part of our competitive advantage, however this is ultimately necessary to instill confidence in our customers. We do require NDAs in place with our customers before doing this.

Understanding Cost Implications:

With increased scrutiny comes increased cost. Achieving compliance can amplify costs by 50-100% compared to Chinese manufacturing. It's vital to maintain an open dialogue with clients, ensuring they grasp the reasons for these added expenses. In most cases, US companies do understand the increased cost, but they win because they can sell their products as truly NDAA and EO13981 compliant.

China’s dominance in the manufacturing sector, characterized by cost-effectiveness and quality, poses a challenge for global competitors. NDAA and EO13981 are essentially nudges urging the Western world to level the playing field. While steering clear of political undertones, it's evident that reinvigorating domestic manufacturing is not just a strategic move but a necessity. At BotBlox, we aim to stay politically neutral. Instead we endeavour to align with the evolving needs of our customers, where NDAA/EO13981 compliance and further, US manufacture, provide them with a huge amount of value.

Check out our NDAA/EO13981 range. If you are interested in getting access to our detailed documentation for a specific board, please get in touch.